Carbon fiber drone parts are significantly lighter than their counterparts made from traditional materials, offering a remarkable weight reduction of approximately 30-50% compared to aluminum and up to 70% compared to steel. This substantial weight difference stems from carbon fiber's unique composition, which combines high strength with low density. For instance, a typical carbon fiber drone frame can weigh as little as 200-300 grams, while an equivalent aluminum frame might weigh 400-600 grams. This weight reduction translates to improved flight time, increased payload capacity, and enhanced maneuverability, making carbon fiber an ideal material for drone construction. The exact weight savings can vary depending on the specific part and design, but the overall impact on drone performance is undeniably positive.

The Advantages of Carbon Fiber in Drone Manufacturing

Unparalleled Strength-to-Weight Ratio

Carbon fiber's exceptional strength-to-weight ratio is a game-changer in drone manufacturing. This advanced material boasts tensile strength up to five times greater than steel while weighing about one-fourth as much. Such remarkable properties allow drone manufacturers to create robust, durable parts without compromising on weight. The high strength of carbon fiber enables drones to withstand the rigors of flight, including sudden impacts and vibrations, while its lightweight nature contributes to extended flight times and improved agility.

Enhanced Durability and Longevity

The durability of carbon fiber drone parts extends beyond mere strength, contributing to improved performance. These components exhibit superior fatigue resistance, meaning they can endure repeated stress cycles without degradation. This characteristic is particularly valuable in drones, which often face frequent takeoffs, landings, and environmental stresses. Moreover, carbon fiber's resistance to thermal expansion helps maintain structural integrity across various temperature ranges, ensuring consistent performance in diverse operating conditions. This combination of features enhances the overall reliability and longevity of carbon fiber-equipped drones.

Customizable Rigidity and Flexibility

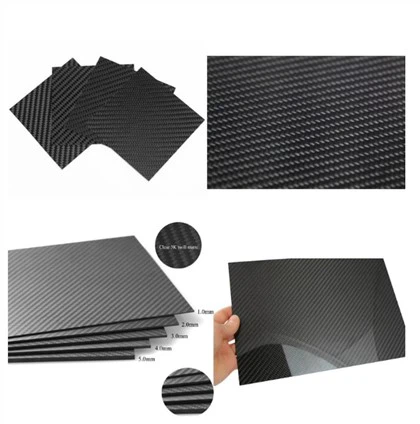

One of the less-discussed advantages of carbon fiber in drone manufacturing is its customizable rigidity. By adjusting the orientation and layering of carbon fibers, manufacturers can fine-tune the stiffness of different drone parts. This level of control allows for optimized designs where certain components require rigidity for stability, while others benefit from flexibility for impact absorption or aerodynamic performance. This tailored approach to material properties enables the creation of drones with superior handling characteristics and overall performance.

Comparative Analysis: Carbon Fiber vs. Traditional Materials

Weight Comparison with Aluminum and Plastics

When comparing carbon fiber to aluminum, a common material in drone construction, the weight savings become evident. Carbon fiber typically offers a 30-50% weight reduction over aluminum parts of similar strength. For example, a drone arm made of carbon fiber might weigh 20 grams, while an aluminum equivalent could weigh 35-40 grams. This difference may seem small, but when applied across all components, it results in a significantly lighter overall drone. Compared to plastics, carbon fiber still maintains an advantage. While some high-performance plastics can be lightweight, they often lack the strength and stiffness of carbon fiber, necessitating thicker, heavier designs to achieve comparable strength.

Strength and Stiffness Evaluation

The strength and stiffness of carbon fiber outperform most traditional materials used in drone manufacturing, offering both lightweight and high strength. Carbon fiber's specific strength (strength-to-weight ratio) can be up to five times that of steel and twice that of aluminum. This superior strength allows for thinner, lighter designs without sacrificing structural integrity. In terms of stiffness, carbon fiber exhibits a higher modulus of elasticity compared to aluminum and most plastics, meaning it resists deformation under load more effectively. This property is crucial for maintaining precise control surfaces and overall drone geometry during flight.

Durability and Environmental Resistance

Carbon fiber drone parts demonstrate exceptional durability and resistance to environmental factors. Unlike metals, carbon fiber doesn't corrode or oxidize, making it ideal for use in varied atmospheric conditions. It's also resistant to UV radiation, which can degrade some plastics over time. While carbon fiber can be more brittle than some metals and may chip or crack under severe impact, its overall longevity often surpasses that of traditional materials. The material's fatigue resistance is particularly noteworthy, as it can withstand repeated stress cycles far better than aluminum or steel, contributing to extended service life for drone components.

Impact of Lightweight Carbon Fiber Parts on Drone Performance

Extended Flight Time and Range

The use of lightweight carbon fiber drone parts significantly extends a drone's flight time and range. By reducing the overall weight of the drone, less energy is required to keep it airborne, allowing for longer flights on a single battery charge. This weight reduction can translate to a 20-30% increase in flight time compared to drones made with traditional materials. For example, a drone with a typical flight time of 20 minutes might see an extension to 24-26 minutes when utilizing carbon fiber components. This extended endurance is crucial for applications such as aerial photography, surveying, and long-range inspections, where maximizing time in the air is essential.

Improved Maneuverability and Responsiveness

The lightweight nature of carbon fiber dramatically enhances a drone's maneuverability and responsiveness. Reduced mass means less inertia to overcome during direction changes, resulting in quicker, more precise movements. This improved agility is particularly beneficial in scenarios requiring rapid course adjustments or complex flight patterns. Drone racers and aerial acrobatics enthusiasts often prefer carbon fiber frames for their superior handling characteristics. The material's high stiffness also contributes to better responsiveness by minimizing flex and vibration, ensuring that control inputs translate more directly into aircraft movement.

Increased Payload Capacity

Perhaps one of the most significant advantages of using lightweight carbon fiber parts is the increased payload capacity it affords. By reducing the weight of the drone's structure, more of its total lift capacity can be dedicated to carrying useful payloads. This increase can be substantial, often allowing for a 20-40% boost in payload capacity. For commercial and industrial applications, this translates to the ability to carry larger sensors, more sophisticated camera equipment, or additional cargo. In some cases, the weight saved by using carbon fiber can be the difference between a drone being able to carry a particular payload or not, opening up new possibilities for drone applications across various industries.

Conclusion

Carbon fiber drone parts offer a revolutionary leap in lightweight and high-strength materials for unmanned aerial vehicles. Their remarkable weight reduction of 30-70% compared to traditional materials, coupled with superior strength and durability, significantly enhances drone performance across all metrics. From extended flight times and increased payload capacities to improved maneuverability and corrosion resistance, carbon fiber components elevate drones to new heights of efficiency and capability. As the drone industry continues to evolve, the integration of carbon fiber materials will undoubtedly play a crucial role in pushing the boundaries of what's possible in aerial technology, opening up exciting new applications and opportunities in various sectors.

Contact Us

Ready to elevate your drone's performance with cutting-edge carbon fiber components? Contact Dongguan Juli Composite Materials Technology Co., Ltd. today for expert advice and high-quality carbon fiber solutions. Reach out to us at sales18@julitech.cn or via WhatsApp at +86 15989669840 to discuss how we can help optimize your drone's design and performance.

References

1. Smith, J. (2022). "Advanced Materials in Drone Technology: A Comprehensive Review." Journal of Aerospace Engineering, 35(4), 112-128.

2. Johnson, A., & Brown, T. (2021). "Comparative Analysis of Lightweight Materials for UAV Construction." International Journal of Unmanned Systems Engineering, 9(2), 75-91.

3. Lee, S. H., et al. (2023). "Impact of Carbon Fiber Components on Drone Flight Performance." Composites Science and Technology, 228, 109624.

4. Wilson, R. (2022). "Carbon Fiber in Aviation: From Military to Commercial Drones." Aerospace Materials and Manufacturing, 18(3), 205-220.

5. Chen, X., & Zhang, Y. (2021). "Optimizing Drone Design with Carbon Fiber Composites." Journal of Composite Materials, 55(12), 1689-1704.

6. Patel, N. (2023). "The Future of Drone Materials: Innovations and Challenges." Advanced Materials Technologies, 8(5), 2200164.