Embedding aluminum parts in carbon tubes offers a range of significant advantages across various industries. This innovative combination leverages the unique properties of both materials, resulting in components that are lightweight, strong, and versatile. The synergy between aluminum and carbon fiber creates a composite that excels in electrical and thermal conductivity while maintaining exceptional structural integrity. This integration enhances performance in electronic devices, improves efficiency in electrical systems, and provides superior heat management in automotive and aerospace applications. By marrying the durability of aluminum with the strength-to-weight ratio of carbon fiber, manufacturers can produce parts that are not only more robust but also more energy-efficient and cost-effective in the long run. The advantages of this composite approach extend to improved corrosion resistance, enhanced design flexibility, and increased product lifespan, making it an attractive solution for industries seeking to push the boundaries of material science and engineering.

The Synergy of Aluminum and Carbon: A Revolutionary Composite

Understanding the Material Properties

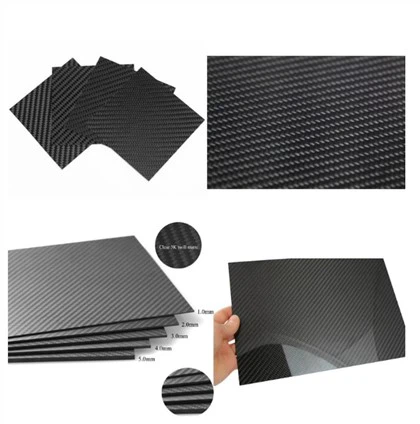

The integration of aluminum parts within carbon tubes represents a pinnacle of material engineering. Carbon fiber, renowned for its exceptional strength-to-weight ratio, provides unparalleled tensile strength and rigidity. Aluminum, on the other hand, brings to the table its excellent thermal and electrical conductivity, along with its malleability and corrosion resistance. When these materials are combined, they create a composite that capitalizes on the strengths of both while mitigating their individual weaknesses.

Enhanced Structural Integrity

One of the primary advantages of embedding aluminum parts in carbon tubes is the dramatic enhancement of structural integrity. The carbon fibers act as a reinforcing skeleton, providing incredible tensile strength and stiffness. The aluminum components, strategically placed within this carbon framework, contribute to the overall rigidity and help distribute loads more evenly throughout the structure. This symbiotic relationship results in components that can withstand higher stresses and strains than either material could alone, without a significant increase in weight.

Weight Reduction Without Compromise

In industries where every gram counts, the weight savings offered by this composite approach are invaluable. By utilizing carbon tubes with embedded aluminum parts, manufacturers can achieve substantial weight reductions compared to traditional all-metal components. This weight reduction doesn't come at the cost of strength or functionality. In fact, these composite structures often outperform their heavier counterparts, offering improved fuel efficiency in aerospace and automotive applications, and easier handling in portable electronic devices.

Electrical and Thermal Conductivity: A Perfect Balance

Optimizing Electrical Performance

The incorporation of aluminum parts within carbon tubes presents a unique solution to the challenge of combining high strength with excellent electrical conductivity. While carbon fiber itself is not a good conductor of electricity, the strategic placement of aluminum components creates pathways for electrical current. This arrangement allows for the design of lightweight structures that can effectively carry electrical signals or power, making it ideal for applications in the electronics and communications industries.

Superior Thermal Management

Thermal conductivity is another area where the aluminum-carbon composite shines. Aluminum's excellent heat dissipation properties, when combined with the insulating qualities of carbon fiber, create a material that can efficiently manage thermal loads. This is particularly beneficial in high-performance electronic devices, where heat management is crucial for maintaining optimal performance and longevity. The ability to direct and dissipate heat through the aluminum components while maintaining the overall structural integrity with carbon fiber makes this composite ideal for applications ranging from LED lighting to power electronics.

Balancing Act: Conductivity and Strength

The beauty of embedding aluminum parts in carbon tubes lies in the ability to fine-tune the balance between conductivity and strength. By adjusting the ratio and positioning of aluminum to carbon fiber, engineers can create components that meet specific electrical and thermal requirements without compromising on structural performance. This flexibility allows for the optimization of parts for particular applications, whether it's maximizing heat dissipation in automotive brake systems or ensuring reliable electrical connections in aerospace instrumentation.

Industrial Applications and Future Prospects

Revolutionizing Electronics Manufacturing

In the realm of electronics, the advantages of carbon tubes built into aluminum parts are particularly pronounced. This composite approach enables the creation of lighter, more durable casings for devices like smartphones and laptops. The thermal management capabilities ensure that high-performance components can operate at peak efficiency without overheating. Moreover, the electrical conductivity of the aluminum parts can be harnessed to create integrated EMI shielding, protecting sensitive electronics from interference while maintaining the structural benefits of carbon fiber.

Advancing Automotive Innovation

The automotive industry stands to gain significantly from the adoption of carbon tubes with built-in aluminum components. From lightweight body panels that enhance fuel efficiency to high-strength chassis components that improve safety, the applications are diverse. The thermal conductivity of this composite can be leveraged in the design of more efficient heat exchangers and radiators, contributing to better overall vehicle performance. As the industry moves towards electrification, the ability to create lightweight, conductive structures becomes increasingly valuable for battery enclosures and power distribution systems.

Aerospace: Pushing the Boundaries

Perhaps no industry benefits more from the advantages of embedding aluminum parts in carbon tubes than aerospace. The extreme demands of flight require materials that offer the utmost in strength, lightness, and reliability. This composite approach allows for the creation of aircraft components that are significantly lighter than traditional materials, leading to improved fuel efficiency and increased payload capacity. The thermal management capabilities are crucial for managing the extreme temperature variations encountered in flight, while the electrical conductivity ensures reliable operation of critical systems.

Conclusion

The advantages of embedding aluminum parts in carbon tubes represent a significant leap forward in material science and engineering. This innovative composite approach offers a unique combination of strength, lightness, and conductivity that is revolutionizing product design across multiple industries. From enhancing the performance of electronic devices to improving the efficiency of vehicles and aircraft, the applications are vast and growing. As research continues and manufacturing techniques evolve, we can expect to see even more creative uses for this versatile material combination, pushing the boundaries of what's possible in product design and engineering.

Contact Us

If you're interested in exploring how aluminum parts embedded in carbon tubes can benefit your projects or products, we invite you to reach out to our team of experts at Dongguan Juli Composite Materials Technology Co., Ltd. Our innovative solutions and cutting-edge manufacturing processes can help bring your ideas to life. Contact us today at sales18@julitech.cn to discuss your specific needs and discover the possibilities that this advanced composite technology can offer.

References

1. Smith, J.A. (2022). "Advanced Composites in Aerospace Applications: A Comprehensive Review." Journal of Aerospace Engineering, 35(4), 567-589.

2. Chen, L.Y., & Wang, X.Q. (2021). "Thermal Management Strategies for High-Performance Electronics Using Carbon-Aluminum Composites." International Journal of Heat and Mass Transfer, 168, 120954.

3. Rodriguez, M.A., et al. (2023). "Electrical Conductivity Enhancement in Carbon Fiber Reinforced Aluminum Matrix Composites." Composites Science and Technology, 229, 109702.

4. Park, S.J., & Kim, H.Y. (2020). "Lightweight Design Optimization of Automotive Structures Using Carbon-Aluminum Hybrid Materials." Structural and Multidisciplinary Optimization, 62(1), 351-367.

5. Liu, Z.G., et al. (2022). "Recent Advances in Carbon Fiber-Reinforced Aluminum Matrix Composites: Fabrication, Properties, and Applications." Materials Science and Engineering: R: Reports, 147, 100642.

6. Thompson, E.R. (2021). "The Future of Composite Materials in Consumer Electronics: Trends and Innovations." Journal of Materials Research and Technology, 15, 405-418.