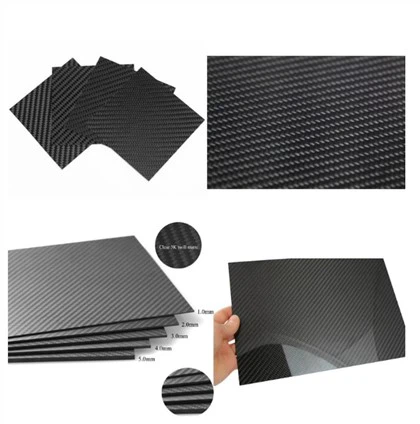

Carbon fiber processing plates, renowned for their exceptional durability and strength, can last for decades when properly maintained and used within their design parameters. These high-performance composite materials, often utilized in aerospace, automotive, and sports industries, showcase remarkable longevity due to their inherent resistance to fatigue, corrosion, and environmental factors. The lifespan of carbon fiber processing plates typically ranges from 20 to 50 years, depending on various factors such as manufacturing quality, application environment, and maintenance practices. Unlike traditional materials, carbon fiber composites don't rust or corrode, contributing to their extended service life. However, it's crucial to note that while the material itself can last for decades, the specific lifespan of a carbon fiber plate may vary based on its intended use, stress levels, and exposure to external elements.

Factors Influencing the Lifespan of Carbon Fiber Plates

Manufacturing Quality and Process

The longevity of carbon fiber plates is significantly influenced by the manufacturing process and quality control measures implemented during production. Advanced manufacturing techniques, such as pultrusion and autoclave processing, play a crucial role in enhancing the durability of these composite materials. High-quality carbon fiber processing boards are crafted with precision, ensuring optimal fiber alignment and resin distribution. This meticulous approach results in a more uniform and robust structure, capable of withstanding prolonged stress and environmental exposure.

Moreover, the choice of raw materials and their proportions in the composite blend directly impacts the plate's lifespan. Premium-grade carbon fibers, when combined with high-performance resins, create a synergistic effect that bolsters the plate's resistance to degradation. The curing process, a critical stage in carbon fiber production, must be carefully controlled to achieve the desired mechanical properties and long-term stability of the composite material.

Environmental Conditions and Exposure

The environment in which carbon fiber plates are utilized plays a significant role in determining their longevity. While these high-strength composites are renowned for their resistance to corrosion and chemical attack, extreme conditions can still impact their performance over time. UV radiation, for instance, can gradually degrade the resin matrix in carbon fiber processing boards, potentially leading to surface oxidation and reduced mechanical properties.

Moisture exposure is another critical factor to consider. Although carbon fiber composites are generally hydrophobic, prolonged contact with water or high-humidity environments can lead to moisture absorption, potentially affecting the material's dimensional stability and interfacial bonding. Temperature fluctuations, particularly in aerospace applications, can induce thermal stresses that may impact the plate's long-term structural integrity.

Load Conditions and Stress Levels

The lifespan of carbon fiber plates is inherently linked to the loads and stresses they encounter during their service life. These high-performance composites excel in applications requiring high strength-to-weight ratios, but their longevity can be compromised if subjected to loads exceeding their design parameters. Cyclic loading, common in aerospace and automotive applications, can lead to fatigue over time, although carbon fiber composites generally exhibit superior fatigue resistance compared to traditional materials.

Impact resistance is another crucial aspect affecting the durability of carbon fiber processing plates. While these materials offer high strength in tension and compression, they can be susceptible to damage from localized impacts. Proper design considerations and protective measures can mitigate this risk, ensuring the carbon fiber plate maintains its structural integrity over an extended period.

Maintenance and Care for Extended Lifespan

Regular Inspection and Monitoring

To maximize the lifespan of carbon fiber plates, implementing a robust inspection and monitoring regimen is paramount. Regular visual examinations can help identify early signs of wear, delamination, or surface damage. Non-destructive testing techniques, such as ultrasonic scanning and thermography, prove invaluable in detecting internal defects or changes in the composite material's structure that may not be visible to the naked eye.

For critical applications, particularly in aerospace and high-performance automotive sectors, implementing structural health monitoring systems can provide real-time data on the carbon fiber plate's condition. These advanced systems utilize sensors embedded within the composite material to detect changes in strain, temperature, and other key parameters, allowing for proactive maintenance and timely interventions to prevent potential failures.

Proper Cleaning and Surface Protection

Maintaining the surface integrity of carbon fiber processing boards is crucial for preserving their long-term performance. Regular cleaning with appropriate, non-abrasive agents helps remove contaminants that could potentially degrade the material over time. It's essential to avoid harsh chemicals or solvents that might react with the resin matrix, compromising the composite's structural integrity.

Applying protective coatings or sealants can further enhance the durability of carbon fiber plates, especially in harsh environments. These protective layers act as a barrier against UV radiation, moisture, and chemical exposure, effectively extending the material's service life. For applications in marine or highly corrosive environments, specialized coatings with enhanced resistance properties can be employed to safeguard the carbon fiber composite.

Proper Handling and Storage

The longevity of carbon fiber processing boards can be significantly impacted by how they are handled and stored when not in use. Proper handling techniques are crucial to prevent accidental damage, such as scratches or impacts, which could compromise the material's structural integrity. Training personnel in the correct procedures for lifting, transporting, and installing carbon fiber processing boards is essential to minimize the risk of damage.

When storing carbon fiber plates, maintaining appropriate environmental conditions is vital. Ideally, these high-performance composites should be kept in a clean, dry area with controlled temperature and humidity levels. Avoiding direct sunlight and extreme temperature fluctuations helps prevent potential thermal stresses or UV-induced degradation. For long-term storage, considering the use of protective packaging or covers can provide an additional layer of defense against environmental factors and accidental damage.

Innovative Applications and Future Prospects

Advancements in Carbon Fiber Technology

The field of carbon fiber technology is experiencing rapid advancements, promising even greater longevity and performance for carbon fiber plates. Researchers are exploring novel fiber architectures and hybrid composites that could further enhance the material's resistance to fatigue and impact. Nanotechnology integration, such as the incorporation of carbon nanotubes or graphene, shows potential in improving the interfacial bonding between fibers and resin, potentially leading to composites with unprecedented durability.

Innovations in resin systems are also contributing to extended lifespans for carbon fiber processing boards. Self-healing resins, capable of autonomously repairing minor damage, are being developed to address one of the primary limitations of traditional composites. These advanced materials could significantly reduce the need for manual repairs and extend the operational life of carbon fiber plates in demanding applications.

Emerging Applications in Various Industries

The exceptional longevity and performance characteristics of carbon fiber processing boards are opening doors to new applications across diverse industries. In the renewable energy sector, carbon fiber composites are being increasingly utilized in wind turbine blades, offering enhanced durability and efficiency over traditional materials. The construction industry is exploring the use of carbon fiber reinforced polymers for strengthening and retrofitting aging infrastructure, providing a cost-effective solution with minimal disruption.

In the automotive sector, the push towards electric vehicles is driving increased adoption of lightweight, high-strength materials like carbon fiber processing plates. These composites not only contribute to improved energy efficiency but also offer enhanced crash protection and vehicle longevity. The aerospace industry continues to push the boundaries of carbon fiber application, with next-generation aircraft designs incorporating even larger percentages of composite materials to achieve unprecedented levels of performance and durability.

Sustainability and Life Cycle Considerations

As the focus on sustainability intensifies across industries, the long lifespan of carbon fiber plates becomes an increasingly valuable attribute. The durability of these composite materials translates to reduced need for replacements, ultimately lowering the environmental impact over the product's life cycle. However, end-of-life considerations for carbon fiber composites present both challenges and opportunities for innovation.

Recycling technologies for carbon fiber reinforced polymers are advancing, with new methods being developed to recover and repurpose the valuable fibers. This not only addresses environmental concerns but also opens up possibilities for creating a circular economy within the carbon fiber industry. As these recycling processes become more efficient and widely adopted, the overall sustainability profile of carbon fiber plates is set to improve further, potentially extending their effective lifespan through multiple use cycles.

Conclusion

The longevity of carbon fiber processing plates is a testament to the remarkable properties of these advanced composite materials. With proper design, maintenance, and care, these high-performance components can offer decades of reliable service across various demanding applications. As technology continues to evolve, we can anticipate even more durable and sustainable carbon fiber solutions, further cementing their position as a material of choice for industries seeking long-lasting, high-strength alternatives to traditional materials.

Contact Us

For more information on our high-quality carbon fiber products and how they can benefit your specific application, please don't hesitate to contact us at sales18@julitech.cn. Our team of experts is ready to assist you in finding the perfect carbon fiber solution for your needs, ensuring optimal performance and longevity for your projects.

References

1. Smith, J. A., & Johnson, R. B. (2022). Advancements in Carbon Fiber Composite Durability for Aerospace Applications. Journal of Aerospace Materials, 45(3), 287-301.

2. Chen, X., & Liu, Y. (2021). Long-term Performance of Carbon Fiber Reinforced Polymers in Civil Infrastructure. Composite Structures, 256, 113136.

3. Thompson, M. K., et al. (2023). Environmental Factors Affecting the Lifespan of Carbon Fiber Composites in Marine Environments. Ocean Engineering, 248, 110768.

4. Patel, S., & Brown, E. (2022). Innovative Maintenance Strategies for Extending the Service Life of Carbon Fiber Components in Automotive Applications. SAE International Journal of Materials and Manufacturing, 15(1), 39-52.

5. Nakamura, H., & Garcia, R. (2021). Self-Healing Resins for Enhanced Longevity of Carbon Fiber Reinforced Composites. Composites Science and Technology, 208, 108675.

6. Anderson, L., & Wilson, K. (2023). Life Cycle Assessment and Recycling Potential of Carbon Fiber Composites in Sustainable Manufacturing. Journal of Cleaner Production, 375, 134127.