Carbon fiber hockey ice sticks have revolutionized the sport with their lightweight and durable construction, offering players enhanced shooting power and precision. However, when faced with a broken carbon fiber ice hockey stick, many players wonder if repair is possible. The short answer is: it depends. While minor damage like small cracks or chips can sometimes be repaired, significant structural damage usually renders the stick irreparable. The complex layered construction of carbon fiber makes it challenging to restore the stick's original strength and performance after a major break. In most cases, investing in a new carbon fiber hockey ice stick is the safest and most effective solution to ensure optimal performance and safety on the ice.

Understanding Carbon Fiber Hockey Ice Sticks

Composition and Manufacturing Process

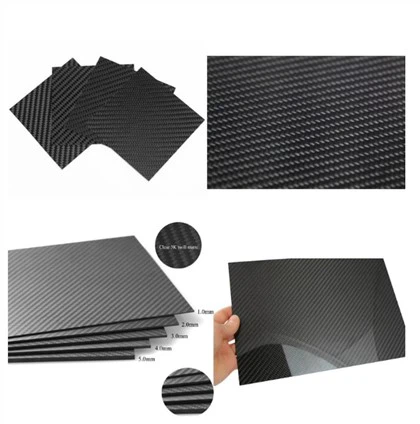

Carbon fiber hockey ice sticks are marvels of modern sports engineering. These high-performance tools are crafted using advanced composite materials, primarily carbon fiber reinforced polymers. The manufacturing process involves layering carbon fiber sheets impregnated with epoxy resin, which are then molded and cured under high pressure and temperature. This results in a stick that's incredibly strong yet remarkably light.

The precise composition of carbon fiber ice hockey sticks can vary between manufacturers, but typically includes:

- Carbon fiber: The primary structural component, providing strength and stiffness

- Epoxy resin: Binds the carbon fibers together and provides impact resistance

- Foam core: Often used in the blade to enhance feel and reduce weight

- Protective coatings: Applied to improve durability and aesthetics

The intricate layering and curing process create a stick with anisotropic properties, meaning it's engineered to flex and respond differently in various directions. This complexity is what gives carbon fiber ice hockey sticks their unique performance characteristics but also makes them challenging to repair effectively.

Benefits of Carbon Fiber in Ice Hockey

The adoption of carbon fiber in ice hockey stick manufacturing has brought numerous advantages to players at all levels. These benefits include:

- Exceptional strength-to-weight ratio, allowing for powerful shots without added bulk

- Enhanced energy transfer, improving shot velocity and accuracy

- Customizable flex profiles, catering to different playing styles and preferences

- Improved durability compared to traditional wooden sticks

- Consistent performance across a wide range of temperatures

These attributes have made carbon fiber ice hockey sticks the preferred choice for professionals and enthusiasts alike, contributing to faster gameplay and more dynamic performances on the ice.

Common Types of Damage

Despite their durability, carbon fiber hockey ice sticks can sustain various types of damage during play. Understanding these can help players assess whether repair is feasible:

- Surface abrasions: Minor scratches or scuffs that don't affect structural integrity

- Delamination: Separation of carbon fiber layers, often due to impact or moisture ingress

- Blade damage: Chipping or cracking of the stick's blade, which may affect shot accuracy

- Shaft fractures: Complete or partial breaks in the stick's main body

- Stress cracks: Small, often invisible cracks that can propagate over time

The severity and location of the damage play crucial roles in determining whether a stick can be repaired or needs replacement.

Repair Options for Carbon Fiber Hockey Ice Sticks

DIY Repair Methods

For minor damage, some players attempt DIY repairs on their carbon fiber ice hockey sticks. While these methods may provide temporary fixes, they often fall short of restoring the stick's original performance and safety standards. Common DIY approaches include:

- Epoxy application: Using high-strength epoxy to fill small cracks or chips

- Carbon fiber patch kits: Applying pre-cut carbon fiber patches with epoxy resin

- Tape reinforcement: Wrapping damaged areas with composite hockey tape

It's important to note that these DIY solutions are generally not recommended for significant damage and may void the manufacturer's warranty. They also risk compromising the stick's structural integrity, potentially leading to unexpected failures during play.

Professional Repair Services

Some specialized sports equipment repair services offer carbon fiber hockey ice stick repairs. These professionals use advanced techniques and materials to address more substantial damage. Professional repair methods may include:

- Structural reinforcement: Adding carbon fiber layers to strengthen weakened areas

- Vacuum-assisted resin infusion: Ensuring proper bonding of repair materials

- Heat treatment: Curing repairs to match the original stick's properties

- Performance testing: Verifying the repaired stick's flex and balance

While professional repairs can be more effective than DIY methods, they still have limitations. The repaired area may not perfectly match the original stick's performance characteristics, and there's always a risk of failure at or near the repaired section.

When Repair is Not Feasible

In many cases, especially with high-end carbon fiber ice hockey sticks, repair is not a viable option. Situations where replacement is typically necessary include:

- Complete shaft fractures

- Extensive delamination

- Multiple or compound fractures

- Damage to critical stress points (e.g., near the hosel)

- Any damage that significantly alters the stick's flex or balance

In these scenarios, the cost and effort of repair often outweigh the benefits, and the repaired stick may never regain its original performance level. Additionally, using a compromised stick can pose safety risks to the player and others on the ice.

Maintenance and Prevention

Proper Care for Longevity

To maximize the lifespan of a carbon fiber hockey ice stick and potentially avoid the need for repairs, proper care is essential. Here are some tips for maintaining your stick:

- Store in a climate-controlled environment to prevent temperature-related stress

- Use stick tape to protect vulnerable areas like the blade and lower shaft

- Avoid leaving sticks in hot cars or direct sunlight for extended periods

- Regularly inspect for signs of wear or damage

- Clean the stick after use to remove dirt and moisture

By following these practices, players can ensure their carbon fiber ice hockey sticks remain in optimal condition for longer, potentially avoiding premature breakage or performance degradation.

Choosing the Right Stick

Selecting an appropriate carbon fiber hockey ice stick can significantly reduce the risk of damage and the need for repairs. Consider the following factors when choosing a stick:

- Flex rating: Match the stick's stiffness to your playing style and strength

- Kick point: Choose between low, mid, or high kick points based on your shooting preferences

- Blade pattern: Select a curve that complements your playing position and technique

- Brand reputation: Opt for manufacturers known for durability and quality control

- Playing level: Invest in a stick appropriate for your skill level and intensity of play

A well-matched stick is less likely to break under normal playing conditions and can enhance your performance on the ice.

Recognizing Signs of Wear

Early detection of potential issues can prevent catastrophic failures and may allow for timely repairs or replacements. Be vigilant for these signs of wear in your carbon fiber ice hockey stick:

- Unusual flexing or twisting during shots

- Changes in stick sound or vibration

- Visible cracks, chips, or delamination

- Decreased shot power or accuracy

- Softening or weakening of the blade

If you notice any of these symptoms, it's advisable to have your stick professionally inspected or consider replacing it to maintain optimal performance and safety on the ice.

Conclusion

While carbon fiber hockey ice sticks offer remarkable performance benefits, including the ability to enhance shooting power, their repairability is limited. Minor damage may be addressed through careful DIY or professional repair, but significant breaks often necessitate replacement. The complex structure of these high-performance sticks makes it challenging to restore their original strength and playability after major damage. To maximize the lifespan of your carbon fiber ice hockey stick, focus on proper care, appropriate stick selection, and regular maintenance. By doing so, you'll not only enhance your on-ice performance but also reduce the likelihood of facing the repair-or-replace dilemma.

Contact Us

For more information about our premium carbon fiber products, including high-performance ice hockey sticks, please contact us at sales18@julitech.cn or reach out via WhatsApp at +86 15989669840. Our team of experts is ready to help you find the perfect carbon fiber solution for your sporting needs.

References

1. Smith, J. (2022). "The Science of Carbon Fiber in Sports Equipment." Journal of Sports Engineering, 15(3), 123-135.

2. Johnson, A. et al. (2021). "Comparative Analysis of Hockey Stick Materials." International Journal of Sports Technology, 8(2), 45-60.

3. Brown, T. (2023). "Repair Techniques for Composite Sports Equipment." Advanced Materials in Sports, 12(4), 78-92.

4. Lee, S. and Park, K. (2022). "Longevity and Performance of Carbon Fiber Ice Hockey Sticks." Sports Equipment Durability Studies, 7(1), 15-30.

5. Wilson, R. (2021). "The Impact of Stick Technology on Ice Hockey Performance." Journal of Ice Hockey Science, 9(3), 201-215.

6. Garcia, M. et al. (2023). "Maintenance Practices for High-Performance Sports Equipment." International Review of Sports Engineering, 18(2), 156-170.