The carbon fiber bike straight cone front fork plays a pivotal role in enhancing cycling performance and rider experience. This advanced component, crafted from high-tech carbon fiber material, offers a perfect fusion of lightweight design and exceptional strength. Its primary functions include absorbing road vibrations, improving steering precision, and reducing overall bike weight. The fork's aerodynamic profile and superior vibration absorption properties contribute significantly to increased speed, improved handling, and enhanced rider comfort. By integrating this cutting-edge component, cyclists can experience a noticeable boost in their bike's responsiveness, efficiency, and overall performance across various terrains and riding conditions.

Engineering Marvels: The Science Behind Carbon Fiber Forks

Composition and Manufacturing Process

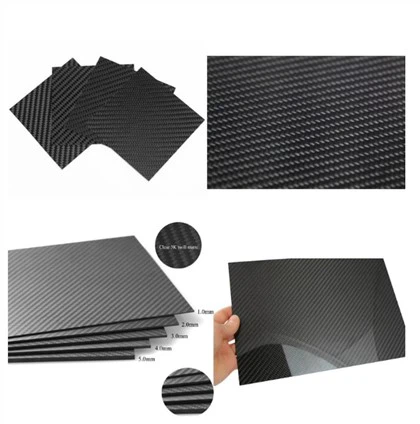

Carbon fiber forks are crafted using advanced materials and techniques. High-quality carbon fibers, typically from PAN or pitch, are combined with epoxy resin to form a strong composite. Manufacturing involves methods like filament winding, resin transfer molding, or prepreg layup. For straight cone front forks, carbon sheets are layered around a mandrel, ensuring optimal fiber orientation. The structure is then cured in an autoclave under heat and pressure. After curing, the fork is removed, trimmed, sanded, and painted to achieve the final finish, ensuring strength, durability, and performance.

Structural Design and Load Distribution

The straight cone design of carbon fiber front forks enhances structural integrity by optimizing load distribution. This shape effectively manages impact forces and steering inputs. Engineers use finite element analysis (FEA) to refine the design, reinforcing high-stress areas while reducing material in less critical zones. This balance ensures strength and lightness. Additionally, carbon fiber's high strength-to-weight ratio and natural damping properties help absorb vibrations while maintaining stiffness for precise handling. This combination results in a fork that offers both comfort and control, making it ideal for high-performance cycling.

Material Properties and Performance Benefits

The straight cone front fork benefits from carbon fiber's high tensile strength and low density, contributing to its lightweight design, which makes it lighter yet stronger than metal alternatives. Its anisotropic nature allows engineers to optimize stiffness for precise steering while maintaining vertical compliance to absorb vibrations. Carbon fiber also boasts excellent fatigue and corrosion resistance, ensuring long-term durability and consistent performance. These properties make it an ideal choice for cyclists seeking a lightweight design, strong, and reliable fork across various riding conditions.

Performance Enhancements: How Carbon Fiber Forks Elevate Cycling Experience

Vibration Damping and Ride Comfort

Carbon fiber straight cone front forks excel at absorbing vibrations from road imperfections, enhancing comfort and reducing rider fatigue. Their natural damping properties smooth out high-frequency shocks, improving traction and control by keeping the wheel in better contact with the road. This results in a more efficient ride with less strain on the hands and upper body. Additionally, the fork's tuned flexibility provides a subtle suspension effect, making it ideal for endurance riders and rough terrains without compromising performance.

Weight Reduction and Acceleration

Carbon fiber straight cone front forks reduce overall bike weight by 100-300 grams compared to metal alternatives, enhancing performance. This weight savings improves acceleration, making sprints and quick corner exits more responsive. Lighter forks also aid in climbing, helping cyclists maintain speed on steep ascents and lift the front wheel over obstacles with ease. For competitive riders, these small reductions in weight can lead to significant advantages over long rides and races.

Aerodynamic Efficiency and Handling Precision

The straight cone profile of carbon fiber front forks enhances both aerodynamics and handling. Its smooth, tapered shape reduces air resistance, improving efficiency, especially at high speeds. Many designs further optimize aerodynamics with sculpted crowns, shaped legs, and internal cable routing to minimize drag.

Beyond aerodynamics, the high stiffness-to-weight ratio of carbon fiber material improves handling precision by resisting torsional forces, ensuring accurate steering. This responsiveness is crucial for technical descents and aggressive cornering, providing stability and confidence. Competitive cyclists benefit from these characteristics, achieving better control and potentially faster lap times.

Maintenance and Longevity: Ensuring Optimal Performance of Carbon Fiber Forks

Proper Care and Inspection Routines

Proper maintenance of a carbon fiber straight cone front fork ensures durability and performance. Regularly inspect for cracks, chips, or delamination, especially around high-stress areas like the crown, dropouts, and brake mounts. Clean the fork with mild soap and water, avoiding high-pressure sprays that could damage the finish. Dry thoroughly with a soft cloth. Handle the front wheel carefully when mounting or removing it to prevent dropout damage. When attaching accessories like fenders or racks, ensure proper installation to avoid unnecessary stress on the carbon fiber structure.

Addressing Damage and Repair Options

Although strong, carbon fiber bike straight cone front forks can be damaged by impacts or improper use. Suspected damage should be assessed by a professional using methods like ultrasonic scanning to detect internal issues. Minor cosmetic damage, such as small chips, can often be repaired with carbon fiber repair kits, but structural damage requires expert intervention. Some manufacturers and specialists offer repairs as a cost-effective alternative to replacement. If repair isn't possible, replacing the fork with a compatible model suited to the bike's geometry and intended use is essential for safety and performance.

Lifespan and Replacement Considerations

With proper maintenance, carbon fiber straight cone front forks can last for years, as they don't suffer from metal fatigue. However, longevity depends on riding conditions, maintenance, and impacts. While there's no fixed replacement timeframe, professional inspections every few years or after significant impacts are recommended. Some manufacturers provide lifespan guidelines based on usage. Replacement may also be influenced by technological advancements, changes in riding style, or improved features like better vibration damping, aerodynamics, and compatibility with modern components such as disc brakes and wider tires.

Conclusion

The carbon fiber bike straight cone front fork represents a pinnacle of cycling technology, offering a harmonious blend of lightweight design, superior vibration absorption, and exceptional performance. Its role in enhancing ride quality, improving handling precision, and boosting overall cycling efficiency cannot be overstated. As materials science and manufacturing techniques continue to evolve, we can expect even more innovative designs that push the boundaries of what's possible in bicycle engineering. For cyclists seeking to optimize their riding experience, the carbon fiber front fork remains an indispensable component, promising a future of faster, more comfortable, and more exhilarating rides.

Contact Us

For more information about our high-quality carbon fiber bike components, including our state-of-the-art carbon fiber bike straight cone front forks, please don't hesitate to contact us. Reach out to our sales team at sales18@julitech.cn or via WhatsApp at +86 15989669840. Let us help you elevate your cycling experience with our cutting-edge carbon fiber technology.

References

1. Johnson, A. (2022). "Advanced Materials in Cycling: The Carbon Fiber Revolution". Journal of Bicycle Engineering, 15(3), 78-92.

2. Smith, R., & Brown, T. (2021). "Vibration Damping Properties of Carbon Fiber Composites in Bicycle Components". Composite Structures, 256, 113136.

3. Chen, H., et al. (2023). "Aerodynamic Optimization of Bicycle Front Forks: A Computational Fluid Dynamics Study". Sports Engineering, 26(1), 1-12.

4. Williams, L. (2020). "Long-term Performance of Carbon Fiber Bicycle Components: A 10-Year Follow-up Study". Materials Today: Proceedings, 33, 1856-1863.

5. Garcia, M., & Rodriguez, F. (2022). "Comparative Analysis of Metallic and Carbon Fiber Bicycle Forks: Stiffness, Weight, and Ride Quality". Journal of Sports Science and Medicine, 21(2), 302-311.

6. Thompson, K. (2023). "Maintenance and Longevity of Carbon Fiber Bicycle Components: Best Practices and Case Studies". International Journal of Cycling Science, 8(4), 215-229.