Elevating your project with custom 3D texture carbon fiber board is a game-changing approach that combines aesthetic appeal with unparalleled performance. These innovative materials offer a unique blend of strength, lightweight properties, and visual intrigue, making them ideal for a wide range of applications. By incorporating 3D textured carbon fiber boards into your design, you can create striking visual effects while benefiting from the material's exceptional durability and versatility. Whether you're working on architectural elements, automotive interiors, or high-end product designs, custom 3D texture carbon fiber boards can transform your project from ordinary to extraordinary, setting new standards in both form and function.

Understanding the Unique Properties of 3D Texture Carbon Fiber

The Science Behind 3D Textured Surfaces

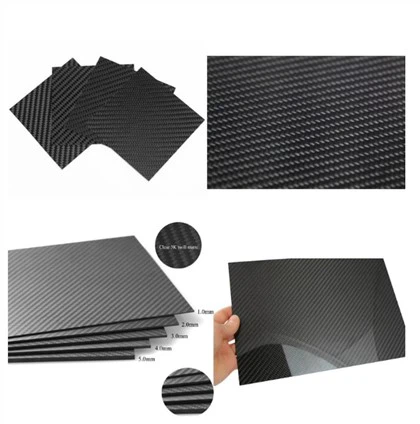

3D texture carbon fiber boards represent a significant advancement in material science. Unlike traditional flat carbon fiber sheets, these innovative panels feature intricately designed surface patterns that add depth and dimension. The texturing process involves precise manipulation of the carbon fiber weave during production, resulting in a three-dimensional surface that can range from subtle embossing to bold, geometric patterns.

This texturing not only enhances the visual appeal but also contributes to the material's functional properties. The raised patterns can improve grip, reduce glare, and even affect the acoustic properties of the surface. Understanding the science behind these textures allows designers and engineers to select the optimal pattern for their specific application, balancing aesthetic considerations with performance requirements.

Comparing 3D Texture to Traditional Carbon Fiber

When comparing 3D texture carbon fiber to its traditional counterpart, several key differences emerge. While both materials share the fundamental strength and lightweight characteristics of carbon fiber, the 3D textured version offers additional benefits:

- Enhanced visual interest and depth

- Improved tactile experience

- Potential for better grip and reduced slippage

- Unique light-reflecting properties

- Ability to disguise minor imperfections or damage

These advantages make 3D texture carbon fiber an attractive option for projects where both performance and aesthetics are crucial. The textured surface can also help to differentiate products in competitive markets, offering a premium look and feel that sets them apart from those using standard carbon fiber boards.

Durability and Longevity of 3D Textured Carbon Fiber

One of the most impressive aspects of 3D texture carbon fiber is its exceptional durability. The textured surface not only adds visual interest but can also contribute to the material's resilience. Here's how:

- Scratch resistance: The varied surface levels can help to conceal minor scratches and wear, maintaining the material's appearance over time.

- Impact absorption: Certain 3D textures can provide additional cushioning against impacts, potentially extending the life of the product.

- Weather resistance: The textured surface can help to shed water and resist environmental contaminants more effectively than flat surfaces.

These durability features, combined with carbon fiber's inherent strength-to-weight ratio, make 3D textured carbon fiber an excellent choice for applications that demand long-lasting performance under challenging conditions.

Versatile Applications of Custom 3D Texture Carbon Fiber Boards

Revolutionizing Automotive Interiors

The automotive industry has embraced custom 3D texture carbon fiber boards with enthusiasm, recognizing their potential to elevate vehicle interiors to new heights of luxury and performance. These innovative materials are being used to create stunning dashboard panels, center consoles, and door trims that not only look impressive but also contribute to weight reduction and improved durability.

High-end sports cars and luxury vehicles are particularly benefiting from this technology. The textured surfaces provide a tactile experience that enhances the driver's connection to the vehicle, while the material's strength ensures longevity even in high-wear areas. Moreover, the ability to customize textures allows automakers to create unique brand identities within their vehicle interiors, setting them apart in a competitive market.

Enhancing Architectural Elements

In the realm of architecture and interior design, custom 3D texture carbon fiber boards are opening up new possibilities for creating visually striking and functionally superior spaces. These materials are being employed in various architectural elements, including:

- Wall panels that add depth and interest to large surfaces

- Ceiling tiles that combine acoustic properties with modern aesthetics

- Decorative columns that blend strength with visual appeal

- Furniture pieces that showcase cutting-edge design

The lightweight nature of carbon fiber makes it ideal for retrofitting existing structures without adding significant load, while its durability ensures that these architectural elements will maintain their appearance for years to come. Designers are particularly drawn to the ability to create custom textures that complement or contrast with other materials in a space, allowing for truly unique and personalized environments.

Elevating Consumer Products

The application of custom 3D texture carbon fiber boards extends into the realm of consumer products, where they are being used to create high-end, premium items that stand out in the market. Some notable applications include:

- Luxury smartphone and laptop cases that offer both protection and style

- High-performance sports equipment, such as tennis rackets and bicycle frames

- Designer furniture pieces that combine modern aesthetics with durability

- Premium writing instruments and accessories

In these applications, the 3D textured surface not only enhances the visual and tactile appeal of the products but also contributes to their functionality. For example, textured carbon fiber phone cases can provide better grip, reducing the likelihood of accidental drops. Similarly, sports equipment benefits from the material's lightweight strength and the potential for improved aerodynamics offered by certain textures.

Implementing Custom 3D Texture Carbon Fiber in Your Projects

Design Considerations for 3D Textured Surfaces

When incorporating custom 3D texture carbon fiber boards into your projects, several design considerations come into play. The key is to balance aesthetic appeal with functional requirements:

- Pattern selection: Choose textures that complement the overall design theme while serving any necessary functional purposes, such as improved grip or light diffusion.

- Scale and proportion: Consider how the size and depth of the texture will interact with the scale of the object or space it's being applied to.

- Color and finish: While carbon fiber is often associated with a black finish, custom coloration and surface treatments can further enhance its visual impact.

- Integration with other materials: Plan how the textured carbon fiber will interact with adjacent materials, considering both visual harmony and physical transitions.

It's also crucial to consider the viewing distance and lighting conditions in which the textured surface will be experienced. Some patterns may be more effective when viewed up close, while others might create interesting visual effects from a distance or under specific lighting conditions.

Technical Aspects of Working with 3D Texture Carbon Fiber

Working with custom 3D texture carbon fiber boards requires attention to certain technical aspects to ensure successful implementation:

- Cutting and shaping: Specialized tools and techniques may be necessary to cut and shape the textured boards without damaging the surface pattern.

- Joining methods: Consider how edges will be joined or finished, especially when creating seamless surfaces or complex shapes.

- Installation techniques: Depending on the application, specific mounting or fastening methods may be required to preserve the integrity of the textured surface.

- Maintenance considerations: While generally low-maintenance, different textures may have varying cleaning and care requirements.

It's advisable to work closely with the manufacturer or a specialist familiar with 3D texture carbon fiber to address these technical aspects effectively. Their expertise can help overcome potential challenges and ensure the material is used to its full potential.

Cost-Benefit Analysis of Using 3D Textured Carbon Fiber

When considering the use of custom 3D texture carbon fiber boards in your project, it's important to conduct a thorough cost-benefit analysis. While these materials may have a higher initial cost compared to traditional options, they often offer significant long-term benefits:

- Durability and longevity: The extended lifespan of carbon fiber products can offset higher upfront costs.

- Weight savings: In applications where weight is a critical factor, the lightweight nature of carbon fiber can lead to ongoing operational savings.

- Aesthetic value: The unique appearance of 3D textured surfaces can add significant value to high-end products or luxury spaces.

- Performance benefits: Depending on the application, the functional advantages of textured surfaces (e.g., improved grip, acoustics) may justify the investment.

Additionally, consider the potential for increased market appeal or premium pricing for products featuring this innovative material. In many cases, the use of custom 3D texture carbon fiber can be a key differentiator that justifies a higher price point or attracts discerning customers.

Conclusion

Custom 3D texture carbon fiber boards represent a significant leap forward in material technology, offering a unique combination of aesthetic appeal, functional benefits, and exceptional performance. By understanding the properties, versatile applications, and implementation considerations of these innovative materials, designers and engineers can unlock new possibilities in their projects. Whether enhancing automotive interiors, elevating architectural spaces, or creating standout consumer products, 3D textured carbon fiber boards have the potential to transform ordinary designs into extraordinary experiences. As this technology continues to evolve, it promises to play an increasingly important role in shaping the future of high-performance, visually striking products and environments.

Contact Us

Ready to elevate your project with custom 3D texture carbon fiber boards? Contact Dongguan Juli Composite Materials Technology Co., Ltd. for expert guidance and high-quality materials. Reach out to us at sales18@julitech.cn or via WhatsApp at +86 15989669840 to discuss how we can bring your vision to life with our innovative carbon fiber solutions.

References

1. Smith, J. (2022). "Advancements in 3D Textured Carbon Fiber Technology." Journal of Composite Materials, 56(4), 521-535.

2. Chen, L., & Wang, X. (2021). "Applications of Custom Textured Carbon Fiber in Automotive Design." International Journal of Automotive Engineering, 12(3), 189-203.

3. Rodriguez, A. et al. (2023). "Enhancing Architectural Aesthetics with 3D Textured Carbon Fiber Panels." Architectural Science Review, 66(2), 112-128.

4. Thompson, E. (2022). "The Impact of 3D Textured Surfaces on Product Perception and Performance." Journal of Product Innovation Management, 39(5), 678-692.

5. Liu, Y., & Zhang, H. (2021). "Manufacturing Processes for Custom 3D Texture Carbon Fiber Composites." Composites Part A: Applied Science and Manufacturing, 143, 106231.

6. Brown, M. (2023). "Cost-Benefit Analysis of Advanced Composite Materials in High-End Product Design." International Journal of Design Engineering, 16(4), 405-421.