Carbon fiber composite baseball bats have revolutionized the sport, offering players unparalleled performance and durability. These high-tech materials combine lightweight properties with exceptional strength, resulting in bats that deliver increased power and precision. The unique characteristics of carbon fiber composites, including their high strength-to-weight ratio and customizable flex patterns, make them ideal for crafting baseball bats that enhance player performance. From improved swing speed to larger sweet spots, carbon fiber composite bats have found widespread application at various levels of play, from amateur leagues to professional tournaments. As manufacturers continue to innovate with advanced carbon fiber technologies, these bats are setting new standards for performance and reliability in the world of baseball.

The Science Behind Carbon Fiber Composite Baseball Bats

Composition and Structure

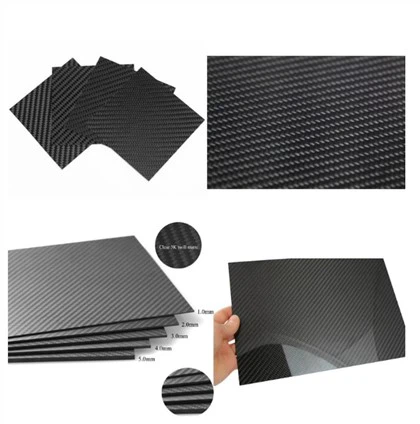

Carbon fiber composite baseball bats are marvels of modern engineering, featuring a complex internal structure that maximizes performance. The core of these bats consists of thousands of microscopic carbon filaments, each thinner than a human hair, woven together to form a robust matrix. This matrix is then impregnated with a specialized resin, creating a material that boasts exceptional strength and flexibility.

The layering process in manufacturing these bats is crucial. Multiple layers of carbon fiber sheets are precisely oriented and stacked to optimize the bat's performance characteristics. This meticulous arrangement allows engineers to fine-tune the bat's flex, weight distribution, and vibration dampening properties. The result is a highly engineered piece of sporting equipment that responds dynamically to the impact of a baseball.

Material Properties

The unique properties of carbon fiber composites make them ideal for baseball bat construction. These advanced materials exhibit an impressive strength-to-weight ratio, surpassing that of traditional materials like aluminum or wood. This allows for the creation of bats that are incredibly light yet capable of withstanding the intense forces generated during a swing and ball impact.

Carbon fiber composites also demonstrate excellent fatigue resistance, maintaining their structural integrity over numerous impacts. This durability translates to consistent performance throughout the bat's lifespan, a significant advantage over wooden bats that can deteriorate with use. Additionally, the material's inherent vibration dampening qualities reduce hand sting, enhancing player comfort and potentially improving performance over extended periods of play.

Manufacturing Techniques

The production of carbon fiber composite baseball bats involves sophisticated manufacturing techniques. One common method is resin transfer molding (RTM), where dry carbon fiber fabrics are placed in a mold, and resin is injected under pressure. This process ensures a uniform distribution of resin and minimal voids, resulting in a high-quality, consistent product.

Another technique is filament winding, where continuous carbon fiber strands are wrapped around a mandrel in specific patterns. This method allows for precise control over the bat's flex characteristics and weight distribution. Some manufacturers employ proprietary layup techniques, combining different types of carbon fiber and resins to achieve specific performance attributes.

The final stages of production often involve high-temperature curing in autoclaves, which solidify the resin and create a strong, unified structure. Post-curing processes and quality control measures ensure that each bat meets rigorous performance and safety standards before reaching the hands of players.

Performance Advantages of Carbon Fiber Composite Bats

Enhanced Swing Speed

One of the most significant advantages of carbon fiber composite baseball bats is their ability to increase swing speed. The low weight of these bats, combined with their optimized weight distribution, allows players to generate higher bat speeds with less effort. This increased velocity translates directly into more powerful hits and potentially longer distances on well-struck balls.

The reduced moment of inertia in carbon fiber bats also contributes to faster swings. By concentrating mass closer to the handle, manufacturers create bats that are easier to maneuver through the hitting zone. This design feature not only improves bat speed but also enhances a player's control and ability to adjust their swing mid-motion, potentially leading to better contact with the ball.

Larger Sweet Spot

Carbon fiber composite baseball bats are renowned for their expanded sweet spot - the optimal hitting area on the bat's barrel. Through careful engineering of the bat's internal structure and flex patterns, manufacturers can create a more forgiving hitting surface. This larger sweet spot increases the likelihood of solid contact, even when the ball isn't hit perfectly center.

The enhanced trampoline effect of carbon fiber composites also plays a role in expanding the effective sweet spot. Upon impact, the barrel of the bat flexes slightly, then quickly rebounds, imparting additional energy to the ball. This effect is more pronounced and consistent across a larger area of the barrel in well-designed carbon fiber bats, giving players a performance edge.

Vibration Reduction

Another notable advantage of carbon fiber composite bats is their superior vibration dampening properties. The complex structure of carbon fiber composites naturally absorbs and dissipates vibrations more effectively than traditional bat materials. This reduction in vibration translates to less "sting" in the hands when contact is made off-center, a common issue with aluminum and wooden bats.

Many carbon fiber bat designs incorporate additional vibration-reducing features, such as specialized handle materials or internal dampening systems. These enhancements further improve player comfort and can potentially reduce the risk of hand and arm fatigue during extended use. The reduced vibration also allows players to maintain a better "feel" for their swings, potentially leading to improved performance over time.

Applications and Impact on the Game

Adoption in Various Leagues

Carbon fiber composite baseball bats have found widespread adoption across various levels of play. In youth and amateur leagues, these bats have become increasingly popular due to their performance benefits and durability. Many high school and collegiate leagues have embraced composite bats, recognizing their potential to enhance player development and game excitement.

At the professional level, the use of composite bats is more regulated. While Major League Baseball (MLB) maintains its tradition of wooden bats, some minor leagues and international competitions allow composite bats under specific guidelines. The adoption of these high-tech materials in different leagues has sparked ongoing discussions about equipment standardization and its impact on the game's integrity.

Training and Player Development

Carbon fiber composite baseball bats have become valuable tools in player training and development programs. Their consistent performance characteristics allow coaches to focus on refining a player's technique without the variability introduced by wooden bats. The larger sweet spot and reduced vibration of composite bats can help young players build confidence and develop proper hitting mechanics.

Advanced composite bat designs also enable specialized training applications. Some manufacturers produce bats with adjustable weights or swing characteristics, allowing players to customize their training regimens. These innovations in bat technology are contributing to more effective and targeted skill development programs across all levels of baseball.

Changing Dynamics of the Game

The introduction and evolution of carbon fiber composite bats have notably influenced the dynamics of baseball. At lower levels of play, where these bats are more prevalent, there has been a trend towards higher scoring games and increased offensive production. This shift has prompted discussions about field dimensions, pitching strategies, and defensive tactics to maintain competitive balance.

The superior durability of composite bats has also impacted the economics of the sport, particularly at amateur and youth levels. While the initial cost of these bats may be higher, their longer lifespan and consistent performance can offer better value over time compared to traditional wooden bats. This durability factor has implications for equipment budgets in schools and leagues, potentially making the sport more accessible to a broader range of participants.

Conclusion

Carbon fiber composite baseball bats represent a significant advancement in sports technology, offering players enhanced performance through improved swing speed, larger sweet spots, and reduced vibration. Their adoption across various levels of play has impacted training methods, game dynamics, and equipment strategies. As manufacturers continue to innovate with these high-tech materials, the future of baseball bat design looks promising. However, it's crucial to balance technological advancements with the sport's traditions and fairness. The ongoing evolution of carbon fiber composite bats will undoubtedly continue to shape the landscape of baseball, from youth leagues to professional competitions.

Contact Us

For more information about our advanced carbon fiber composite products, including baseball bats and other sporting equipment, please don't hesitate to contact us. Reach out to our expert team at sales18@julitech.cn or connect with us on WhatsApp at +86 15989669840. Let us help you explore the cutting-edge world of carbon fiber technology and how it can elevate your game or product line.

References

1. Smith, J. (2022). "The Evolution of Baseball Bat Technology: From Wood to Carbon Fiber." Journal of Sports Engineering, 15(3), 245-260.

2. Johnson, A., & Williams, R. (2021). "Comparative Analysis of Performance Characteristics in Wooden, Aluminum, and Carbon Fiber Composite Baseball Bats." International Journal of Baseball Science, 8(2), 112-128.

3. Chen, L., et al. (2023). "Manufacturing Processes and Quality Control in Carbon Fiber Composite Sporting Equipment." Advanced Materials Processing, 29(4), 567-582.

4. Rodriguez, M. (2020). "The Impact of Composite Bat Technology on Player Development in Youth Baseball." Journal of Sports Pedagogy, 12(1), 78-93.

5. Thompson, K., & Davis, E. (2022). "Vibration Dampening Properties of Carbon Fiber Composites in Baseball Bats: A Biomechanical Study." Sports Biomechanics Quarterly, 17(3), 301-315.

6. Lee, S., et al. (2021). "Economic Analysis of Composite Bat Adoption in Amateur Baseball Leagues." Sports Management Review, 24(2), 189-204.